How to make a stainless steel urinal

2022-03-02

At present, stainless steel urinals are one of the main sanitary appliances used in men's toilets in public places such as squares, schools, hospitals, shopping malls, supermarkets, etc. Their design uses grooved cement, ceramic toilets and stainless steel fixed materials used by multiple people at the same time. Then, let's take a look at the production method of stainless steel urinals!

When men urinate, if they do not pay attention to public health, the urine will overflow, pollute the ground and the overall structure, and cause great inconvenience to the cleaning workers. Over time, it is easy to cause bacterial nourishment and bacterial macular degeneration and spread. It is not suitable for the rapid development of society and the construction of a spiritually civilized society. Unclean corners are also prone to appear in the toilet. After long-term use, chemical cleaners need to be used to remove dirt. However, the current small buckets are mostly made of stainless steel or ceramic materials, which have poor tolerance to uric acid and alkali components, easy to accumulate dirt, not easy to clean, and easy to cause damage to the small buckets.

The public health problem of public places, especially public toilets, is a matter of great concern in China, and how to reduce the reproduction and spread of urine bacteria is an urgent public problem to be solved.

Stainless steel urinal technology implementation elements:

The purpose of the utility model: To provide a stainless steel urinal, which has the advantages of easy cleaning, not easy to breed bacteria, easy to clean, long life, beautiful and practical appearance, etc.

In order to achieve the above purposes, the technical scheme of the utility model is as follows.

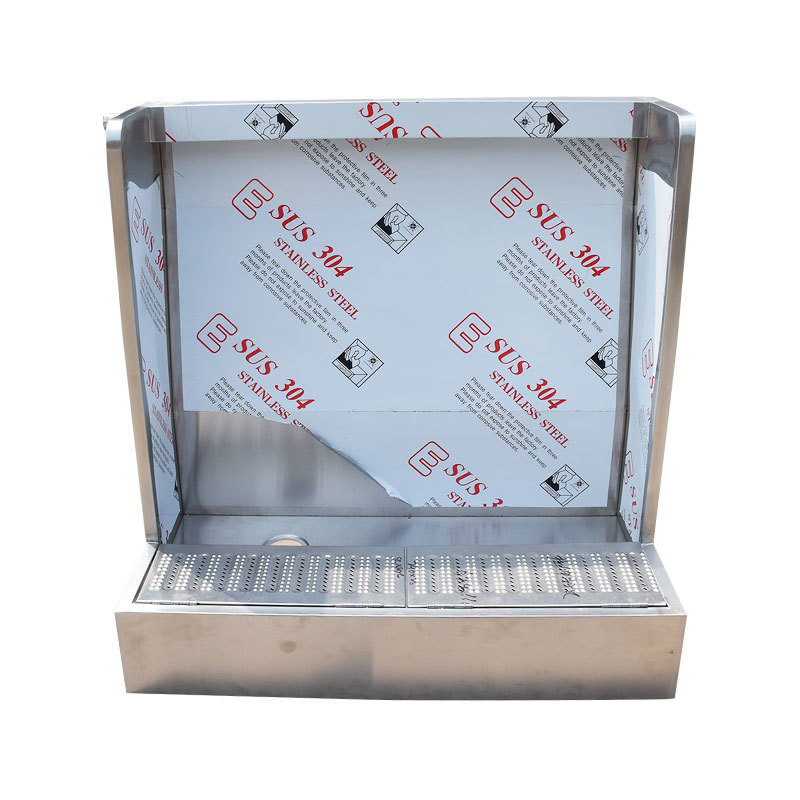

The stainless steel urinal comprises a water pipe, a connecting screw, a metal square pipe, a metal cover plate, a sprayer, a metal bottom groove, a metal step, a glass partition wall and a side baffle; the water pipe is mounted horizontally on a wall at least 1200mm from the ground, and the water pipe is a round pipe structure; the metal square pipe comprises an upper metal square pipe and a lower metal square pipe, the upper metal square pipe is arranged below the water pipe; the metal cover is mounted above the water pipe through a plurality of the connecting screws, and the metal cover is a rectangular body structure; the water supply pipe is through the The hook is mounted on the bottom surface of the metal cover, one end of the water supply pipe is connected to the water supply pipe, the water supply pipe is equally opened along the axial direction with a plurality of outlet holes, the water supply pipe is a round pipe structure; the metal bottom groove and the metal pedal are arranged on the ground, the cross-section of the metal bottom groove is roughly trapezoidal, the front end of the trapezoid is at right angles and is recessed in a stepped shape, with a groove wall and chamber mounted on the wall.

The inner cavity of the stainless steel urinal as a whole is long and grooved, with a liquid discharge port at its bottom, and a template member for filtering metal at the liquid discharge port. The cross-section of the inner cavity is trapezoidal in shape; the metal pedal is arranged at the front end of the metal bottom groove, and the metal pedal is a rectangular body structure; the lower metal square tube is arranged on the upper end face of the metal bottom groove wall, the upper end face of the groove wall is the same width as the metal square tube; the glass water barrier wall is mounted between the upper metal square tube and the lower metal square tube through a plurality of the fastening screws , The glass water barrier wall and the metal bottom groove are connected into one, the step length of the groove wall is the same as the thickness of the glass water barrier wall; the side baffle is arranged on the left end face and the right end face of the metal bottom groove, the side baffle is a rectangular body structure.In the above-mentioned stainless steel glass urinal, the above-mentioned metal pedal has a thickness of at least 15mm.

In the above-mentioned stainless steel urinal, one or more drainage holes are preferably provided along the axial direction on the sprinkler pipe, and there are intervals between the adjacent sprinkler holes, and the sprinkler holes are located below the drain pipe.

In the stainless steel urinal, the glass partition wall may also be perpendicular or inclined with respect to the metal cover.

In the above-mentioned stainless steel urinal, the flanks are made of metal or glass material.

The spray tube is arranged on the bottom surface of the metal cover through a hook; the hook comprises a head suspension portion and a connecting portion at the rear end, and the connecting portion is a threaded shaft.

In the above-mentioned stainless steel glass urinal, the height of the above-mentioned glass partition wall is at least 100mm and the thickness is at least 10mm.

In summary, the utility model has the advantages of using metal and glass materials as a whole, beautiful appearance, and greatly improved life through the redesign of the existing stainless steel urinal in terms of material and structure. In addition, glass and metal materials are easy to clean in real time, effectively preventing bacteria from multiplying.

The above describes the production method of stainless steel urinals. If you need to know more, you can contact us at any time!